Vakuumtechnik

Präzision auf molekularer Ebene. Reproduzierbare Verfahren.

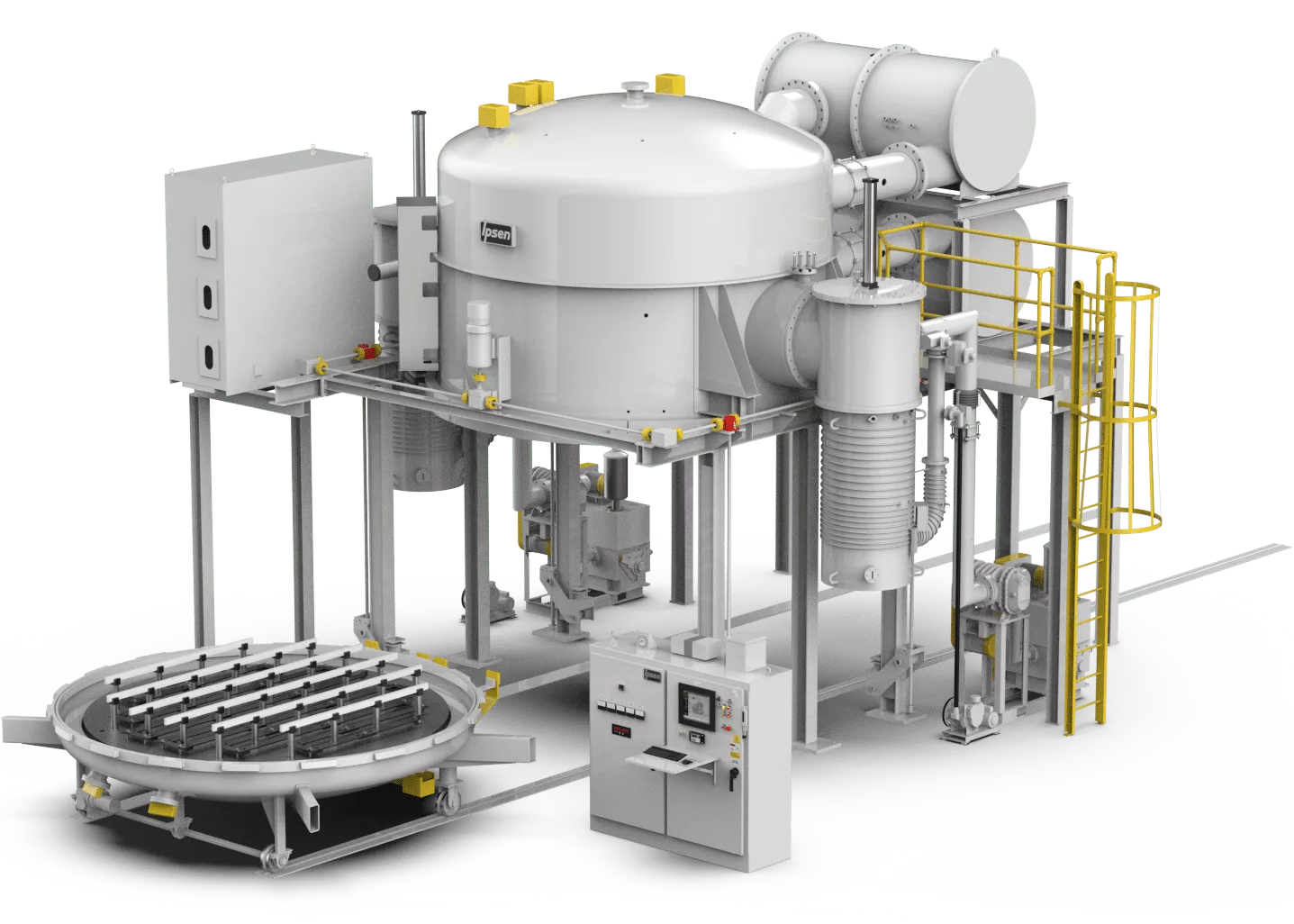

Unsere Vakuumöfen sind so konzipiert, dass Ihre Bauteile allen sicherheitskritischen und leistungsstarken Ansprüchen standhalten können. Wir unterstützen Sie bei allen Fragen rund um Ihre Anlagen für die gesamte Lebensdauer

AnfrageHöchste Qualität mit Anlagen von Ipsen! Wir sind Ihr verlässlicher Partner rund um das Thema Wärmebehandlung.

Ofenspezifikationen

Ipsen-Vakuumöfen eignen sich für eine breite Palette von Wärmebehandlungsverfahren, darunter:

- Glühen

- Löten

- Aufkohlung

- Härten

- Sintern

- Oberflächenbehandlungen

- Anlassen

Vakuum-Aluminium-Löten (VAB)

Alle Vakuum-Aluminiumlötöfen sind mit individuell gesteuerten Heizelementen ausgestattet, die den Arbeitsbereich umgeben und so die Zykluszeiten minimieren und eine präzise, gleichmäßige Erwärmung des Werkstücks ermöglichen. Fugenlose Heizelemente verhindern Widerstandsbildung und "hot spots".

Lösungsnitrieren (SolNit®)

SolNit ist ein thermo-chemisches Wärmebehandlungsverfahren, das dem Einsatzhärten ähnelt, bei dem jedoch Stickstoff anstelle von Kohlenstoff als Legierungsmittel verwendet wird. Bei diesem Verfahren werden Vakuumöfen mit Hochdruck-Gasabschreckung für das Nitrieren nichtrostender Stähle verwendet. So kann auch minderwertiger nichtrostender Stahl gehärtet werden, der in allen Bereichen von chirurgischen Instrumenten bis hin zu Haushaltsgeräten eingesetzt wird.

Vakuumaufkohlung mit Acetylen (AvaC®)

Unser patentrechtlich geschütztes AvaC-Vakuumaufkohlungsverfahren verwendet Acetylen, um das von Propan bekannte Problem der Ruß- und Teerbildung praktisch zu beseitigen und gleichzeitig die Aufkohlungsleistung selbst bei Sackloch- oder Durchgangsbohrungen erheblich zu steigern. Es gewährleistet eine äußerst homogene Aufkohlung auch bei Teilen mit komplexen Geometrien und hohen Belastungsdichten.

Aluminium-Ionen-Dampfabscheidung (IVD)

Aluminium-Ionen-Dampfabscheidung (IVD) ist ein Verfahren zum Aufbringen von Beschichtungen aus reinem Aluminium auf Teile zum Schutz vor Korrosion. Um eine Verunreinigung durch Sauerstoff und Wasserdampf zu vermeiden, wird die Aluminiumbeschichtung im Vakuum auf die Teile aufgebracht.

Entbindern und Sintern

Das Vakuumentbindern und -sintern ist ein Verfahren, das für pulverförmige Metallteile, MIM-Komponenten, 3D-Metalldruck und Sickenanwendungen eingesetzt wird. Die Teile werden auf die Verdampfungstemperatur des Bindemittels erhitzt und auf diesem Niveau gehalten, bis das Bindemittel vollständig ausgegast ist. Anschließend wird die Temperatur auf die Sintertemperatur der Basislegierung erhöht und gehalten, um die Diffusion der Teile in den festen Zustand zu gewährleisten.

Wir produzieren unsere Standard-Vakuumöfen mit einer engen Temperaturgleichmäßigkeit von ±6 °C (±10 °F) und einer Hochtemperaturverarbeitungsfähigkeit von bis zu 1.316 °C (3.000 °F). Einige Ofenmodelle, wie z. B. unsere Vakuum-Aluminiumlötanlage, können bei ±5 °F (3 °C) arbeiten.

Graphit-Heizkammern

Graphit-Heizkammern sind langlebig und bieten eine hervorragende Kapitalrendite. Sie sind robust, wirtschaftlich zu reparieren und verfügen über Herdkonstruktionen mit hoher Lebensdauer.

Ganzmetallische Molybdän-Heizkammern

Ist Ihr Prozess anfällig für Graphitverunreinigungen , kann eine Molybdän-Heizkammer Ihre Anforderungen erfüllen. Unsere Molybdän-Heizkammer-Elemente haben ein "Doppel-U"-Profil, wodurch sie leicht zu installieren und zu ersetzen sind.

Kundenspezifische Konstruktionen

Wir bieten kundenspezifische Heizkammer-Konstruktionen, wie z. B. Graphitisolierung mit Moly-Heizelementen, für Anwendungen mit besonderen Anforderungen.

Starten Sie Ihr Projekt

Unsere Lösungen Ihre Inspiration. Unsere Lösungen Ihre Stärke. Unsere Lösungen Ihre Sicherheit.

Zuverlässige, präzise und langlebige Vakuumlösungen.

Blog-Beitrag

Die Wahl des richtigen Vakuumofens für Ihre Bedürfnisse

Die Wahl des richtigen Ofens ist entscheidend für den Erfolg Ihres Unternehmens und die Qualität Ihrer Teile - und es gibt eine große Auswahl. Beim Kauf eines...

Mehr lesen

Wenden Sie sich noch heute an einen Experten.

Wir helfen Ihnen, Ihre nächste Investition in einen Vakuumofen so zu optimieren, dass sie den größtmöglichen Nutzen für Ihr Unternehmen bringt. Unsere Experten werden gemeinsam mit Ihnen, die bestmöglichen Lösungen erabeiten. Nehmen Sie noch heute Kontakt mit uns auf.

Anfrage